Contents List

- 1 What Is a Cricket Ball Made Of?

- 2 The History Behind the Cricket Ball

- 3 What Is a Cricket Ball Made Of?

- 4 How Is a Cricket Ball Made? Step-by-Step Process

- 5 Inside a Cricket Ball: The Hidden Science

- 6 Why Different Colors? Red, White, and Pink Balls Explained

- 7 The Science Behind the Swing and Spin

- 8 How Weather Affects the Ball

- 9 Top Cricket Ball Manufacturers in the World

- 10 How Long Does a Cricket Ball Last?

- 11 Quick Recap: What Makes a Cricket Ball Special

- 12 FAQs: Everything You Ever Wondered About Cricket Balls

- 13 Final Thoughts: The Hidden Beauty Behind Every Delivery

What Is a Cricket Ball Made Of?

Have you ever wondered what’s really inside a cricket ball — that little red (or white) globe that decides the fate of matches? To the naked eye, it might just look like a simple leather ball. But once you explore deeper, you’ll find that it’s actually a masterpiece of precision, balance, and skill.

Every delivery you see — whether it’s a 90-mph thunderbolt from Mitchell Starc or a perfectly looping off-spinner from Ravichandran Ashwin — is made possible because of the ball’s perfect design. The swing, the seam movement, the bounce — none of it happens by accident.

In this post, we’ll open up the cricket ball layer by layer, explore how it’s made, what it’s made of, and why it behaves the way it does. By the end, you’ll never look at a cricket ball the same way again. Let’s dive in — literally inside the heart of every delivery.

The History Behind the Cricket Ball

Before the shiny red ball became the symbol of Test cricket, it had a long and fascinating journey. In the early 18th century, cricket balls were handmade by local craftsmen who used a cork core wrapped in twine and covered it with a leather casing. That basic design still stands today — proof that the early makers got it right.

As the sport grew, so did the need for consistency. English manufacturers, such as Dukes, began producing high-quality, hand-stitched balls in the 1770s. Across the world, brands like Kookaburra (Australia) and SG (India) followed, each adding their own twist to the design.

Did you know?

👉 The very first recorded cricket ball makers were in Kent, England, around 1760. Those early balls often had irregular seams and shapes — and bowlers used that to their advantage!

Over time, the ball evolved in tandem with the game itself. The seam became more defined, the leather tougher, and the weight standardized (around 155.9g to 163g for men’s cricket). Even the polishing techniques changed as players discovered how a shiny surface could affect the ball’s trajectory in the air.

Today, whether it’s a Dukes ball in England, a Kookaburra in Australia, or an SG ball in India, each one carries centuries of craftsmanship — stitched with history and perfected by science.

What Is a Cricket Ball Made Of?

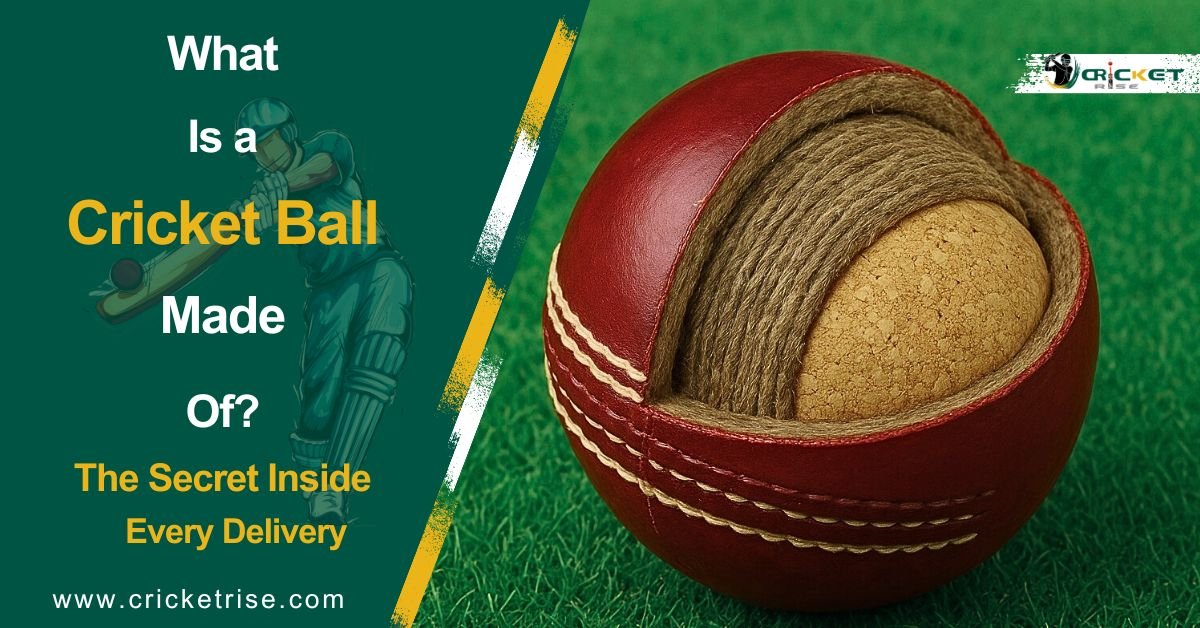

At its core, a cricket ball is a combination of four main materials — cork, twine (yarn), leather, and thread. But the real magic lies in how these materials are combined. Let’s peel it open layer by layer:

a) The Core: Solid Cork Power

Every cricket ball starts with a small, solid cork core — think of it as the heart of the ball. Cork is chosen because it’s light, bouncy, and naturally shock-absorbent. The core gives the ball its spring and helps it bounce off the pitch with energy.

High-quality balls often utilize a combination of cork and rubber for enhanced durability. This core is then compressed under high pressure to form a perfectly round shape.

b) Layers of Twine (Yarn): The Strength Within

Once the cork core is ready, it’s tightly wrapped in several layers of wool or polyester yarn. These layers are what give the ball its hardness and consistent shape. The winding has to be even — any imbalance can affect swing and bounce later.

The winding process is performed with such precision that the tension of each layer can significantly impact how the ball behaves on the pitch. In fact, some manufacturers even fine-tune the tightness of these layers for different match formats.

c) The Leather Cover: Beauty Meets Durability

Now comes the outer layer — leather, usually cowhide, which gives the cricket ball its signature look and feel. The leather is dyed (in red, white, or pink, depending on the format), polished, and cut into four quarter panels.

These panels are carefully stitched together around the core using a strong linen thread.

d) The Seam: The Spinner’s Secret Weapon

The seam is where art meets science. It’s made by 80 to 90 precise stitches, creating a raised ridge around the ball’s center.

This ridge is not just decoration — it’s what allows bowlers to grip the ball and control movement through the air. The seam helps the ball swing and cut off the pitch, giving bowlers that crucial edge over batters.

Fun fact:

👉 A cricket ball’s seam isn’t perfectly symmetrical. One side is slightly raised, and bowlers use that to control which way the ball swings.

e) Polishing and Finishing Touches

Finally, the stitched ball is polished with wax or lacquer to create a shiny finish. That shine is not just for looks — it protects the leather and helps with aerodynamics.

Once ready, each ball is tested for weight, circumference, hardness, and bounce before it earns the right to be used in an international match.

How Is a Cricket Ball Made? Step-by-Step Process

We’ve talked about the ingredients — now let’s look at how these elements come together to form that perfect red sphere.

Step 1: Shaping the Core

The process begins with forming a cork ball, sometimes mixed with rubber for strength. The mixture is pressed into a round shape and then dried.

Step 2: Winding the Yarn

Next, multiple layers of tightly wound yarn are wrapped around the cork. The winding process is critical — too tight and the ball becomes too hard; too loose and it loses bounce.

Step 3: Cutting the Leather Panels

Four quarter-shaped leather pieces are cut and soaked to make them soft and stretchable. Each piece is perfectly measured to ensure balance.

Step 4: Stitching the Leather and Seam

This is the most skillful part. Two halves of leather are stitched together using strong waxed thread. Then, the main seam — that beautiful raised line around the middle — is hand-stitched with 80 to 90 double stitches.

Each manufacturer has its own stitching pattern, which slightly changes the ball’s aerodynamics. That’s why Dukes’ balls swing more in England, while Kookaburras tend to behave differently under hot, dry conditions.

Step 5: Polishing and Testing

After stitching, the ball is pressed again to perfect its shape. Then, it’s coated with wax, lacquer, or grease to create that glossy surface bowlers love.

Every ball is tested for:

- Weight (155.9g–163g)

- Circumference (22.4–22.9 cm)

- Bounce consistency

- Seam alignment

Only the best ones pass inspection and are branded for professional use.

Did you know?

👉 A high-quality cricket ball can take four to five hours to make — all by hand!

Inside a Cricket Ball: The Hidden Science

You might think a cricket ball is all about tradition, but science also plays a significant role.

When a bowler releases the ball, its aerodynamic design interacts with air resistance, seam angle, and speed to create movement — that’s where swing and seam come from.

The shiny side of the ball reduces air drag, while the rough side increases it. The difference between the two sides creates pressure variation, making the ball deviate in the air — the beautiful art of swing bowling.

- Conventional Swing: Happens when the shiny side faces the batter and the seam is angled slightly.

- Reverse Swing: Appears when the ball gets older — the rough side faces the batter, and the airflow reverses direction, fooling even the best batters.

Physics aside, everything — from the density of cork to the polish of leather — influences how the ball behaves. The materials work together to maintain a perfect balance between hardness for bounce and flexibility for control.

Fun fact:

👉 A cricket ball can rotate at over 2,000 revolutions per minute (RPM) when delivered by a fast bowler. That’s what gives it both speed and swing!

So next time you see a bowler kiss the shiny side before their run-up, know this — they’re not just showing love; they’re maintaining the aerodynamics of their weapon.

Why Different Colors? Red, White, and Pink Balls Explained

Every cricket fan notices that Test matches use red balls, ODIs and T20s use white balls, and day-night Tests use pink balls. But have you ever wondered why?

Red Ball – The Classic Choice

The red cricket ball is the oldest and most traditional type of cricket ball. It’s made from dyed leather and performs best in longer formats, such as Test cricket.

- It swings more under natural light.

- It’s durable and holds shine longer.

- The red color contrasts well with white clothing.

White Ball – The Limited-Overs Star

White balls are used in ODIs and T20s, especially for day-night matches. They’re easier to spot under floodlights and TV cameras.

However, they wear out faster than red balls and need frequent replacement due to color fading and less durable coating.

Pink Ball – The Hybrid Innovation

The pink ball was introduced for day-night Test matches. It combines the visibility of the white ball with the endurance of the red one.

To make the pink color stand out under lights, manufacturers use a special fluorescent dye and an extra layer of lacquer, resulting in a glossier, slightly harder finish.

Did you know?

The first-ever day-night Test match with a pink ball was played between Australia and New Zealand in 2015 at Adelaide Oval.

The Science Behind the Swing and Spin

A cricket ball isn’t just a round object — it’s an aerodynamic masterpiece. Let’s break down how its design helps it behave the way it does.

Swing Bowling

Swing happens because of the difference in air pressure on the two sides of the ball.

- The shiny side is smoother, allowing air to flow more easily.

- The rough side slows the air down.

This imbalance causes the ball to curve mid-air, confusing the batter. Bowlers like James Anderson have made careers out of mastering this art.

Spin Bowling

Spinners use their fingers or wrists to make the ball rotate rapidly. The seam and surface friction make it deviate after bouncing, especially on dusty or worn-out pitches.

So, every time you see a bowler take a wicket with a clever delivery, remember — it’s not just skill; it’s also the incredible engineering inside that ball.

How Weather Affects the Ball

Have you ever noticed how some pitches or weather conditions seem to favor bowlers? That’s because temperature and humidity can alter how the cricket ball behaves.

- In dry, hot weather, the ball becomes harder and bounces higher.

- In humid conditions, it tends to swing more due to increased air density.

- In damp weather, the leather absorbs moisture, reducing swing but improving spinners’ grip.

So next time rain delays a match, you’ll know — even the ball’s chemistry changes with the weather!

Top Cricket Ball Manufacturers in the World

Some brands have become legends in their own right. Their balls are trusted in international and domestic tournaments alike.

1. Dukes (England)

Hand-stitched and traditional, Duke’s balls are used in England and the West Indies. Known for their long-lasting swing and pronounced seam.

2. Kookaburra (Australia)

Machine-stitched but precise, Kookaburra balls are popular in Australia, New Zealand, and South Africa. They have a smoother seam and consistent bounce.

3. SG (India)

The official red ball used in Indian Test matches. Hand-stitched with a slightly thicker seam, ideal for subcontinental pitches.

4. Gray-Nicolls & Readers

Used in club and first-class cricket across the globe — reliable, durable, and affordable.

How Long Does a Cricket Ball Last?

The lifespan of a cricket ball depends on its format:

- Test Matches: 80 overs (after which replacement is allowed).

- ODIs: Around 25–30 overs before noticeable wear.

- T20s: Around 15–20 overs due to constant hitting.

In local cricket, one ball might even last several matches — though its shine and swing fade quickly.

Quick Recap: What Makes a Cricket Ball Special

| Component | Material | Function |

|---|---|---|

| Core | Cork + Rubber | Provides bounce and weight |

| Yarn | Wool | Maintains round shape |

| Leather | Cowhide | Outer cover and shine |

| Seam | Thread (Waxed) | Helps with swing and grip |

| Polish | Wax/Lacquer | Aids visibility and durability |

FAQs: Everything You Ever Wondered About Cricket Balls

1. Are all cricket balls the same size?

No. Men’s, women’s, and junior cricket balls differ slightly in weight and circumference.

2. Can a cricket ball break?

Yes, under extreme impact or misuse, the seam or leather can split.

3. What’s the difference between match balls and practice balls?

Match balls are handcrafted from top-quality leather, whereas practice balls are often machine-made or made from synthetic materials.

4. Do bowlers prefer a new ball or an old ball?

Fast bowlers love the new ball for swing; spinners enjoy the old ball for grip and turn.

Final Thoughts: The Hidden Beauty Behind Every Delivery

Next time you watch a fast bowler charge in, or a spinner trick a batter, take a moment to appreciate the craft inside that little sphere. From hand-picked leather to the final polish, every cricket ball is a piece of art — shaped by precision, patience, and passion. It’s not just a ball; it’s the heartbeat of cricket — the one thing that connects every bowler, batter, and fan across the world.